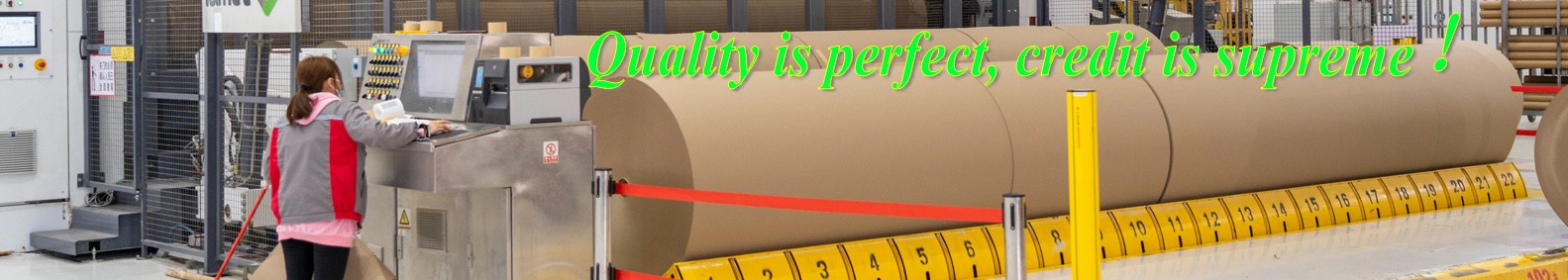

kraft paper

Kraft paper is a high-strength, durable packaging paper named for its resemblance to cowhide in color and texture. It is made from sulfate wood pulp and is known for its excellent toughness and eco-friendly properties. It is widely used in packaging, construction, art, and many other fields. Below is a detailed introduction to kraft paper:

1. Definition

Kraft paper is a type of paper made from unbleached or bleached sulfate wood pulp, typically brown (unbleached) or white (bleached) in color. It is characterized by its long fibers, high strength, tear resistance, and wear resistance.

2. Features

High Strength: The tight fiber structure of kraft paper gives it high tensile strength and burst resistance.

Eco-Friendliness: Made from natural wood pulp, it is recyclable and biodegradable, meeting environmental standards.

Tear Resistance: Its long fibers and good toughness make it difficult to tear.

Water Resistance: Some kraft paper is specially treated to have water-resistant properties.

Printability: Although the surface is rough, it is suitable for simple printing, often used for packaging labels and logos.

3. Types

Based on usage and performance, kraft paper can be categorized as follows:

Unbleached Kraft Paper: Natural brown in color, high strength, commonly used for industrial packaging.

Bleached Kraft Paper: Treated with bleach, white in color, suitable for high-end packaging and printing.

Greaseproof Kraft Paper: Specially treated to resist oil, used for food packaging.

Waterproof Kraft Paper: Coated to provide waterproof functionality, suitable for humid environments.

Art Kraft Paper: Available in various colors and softer textures, used for crafts, painting, and decoration.

4. Applications

Kraft paper is widely used in the following fields:

Packaging Industry: Such as paper bags, envelopes,快递 bags, and food packaging.

Construction Industry: Used as waterproof layers, protective layers, or temporary coverings.

Art and Crafts: Used for painting, handmade projects, bookbinding, etc.

Industrial Field: Used as abrasive paper backing, cable wrapping material, etc.

Agricultural Field: Used for soil covering or crop protection.

5. Production Process

The production of kraft paper mainly includes the following steps:

Pulping: Wood is turned into sulfate wood pulp, retaining long fibers.

Papermaking: The pulp is diluted and formed into paper using a paper machine.

Calendering: The paper is passed through a calender to improve smoothness and density.

Coating Treatment (Optional): Special treatments like waterproofing or greaseproofing are applied as needed.

Cutting: Large rolls of paper are cut into the required sizes.

6. Considerations for Purchase

Grammage: The grammage of kraft paper varies widely, typically ranging from 60g/m² to 300g/m². Choose the appropriate grammage based on the intended use.

Color: Unbleached kraft paper is brown, while bleached kraft paper is white. Select based on requirements.

Special Properties: If waterproof or greaseproof properties are needed, choose specially treated kraft paper.

Eco-Certifications: Opt for products that meet environmental standards, such as FSC-certified kraft paper.

7. Market Status

Due to its eco-friendliness and versatility, the demand for kraft paper continues to grow. With increasing environmental awareness, renewable and biodegradable kraft paper is being increasingly used in packaging and industrial fields.

8. Environmental Advantages

Renewable: Made from natural wood pulp, it is a sustainable resource.

Biodegradable: It decomposes naturally after disposal, reducing environmental pollution.

Recyclable: It can be recycled multiple times, reducing resource waste.

In summary, kraft paper is a high-strength, eco-friendly, and versatile paper widely used in packaging, construction, art, and other fields. Its excellent performance and environmental properties make it an essential material in modern industry and daily life.